Hammer Milling For Cannabis & Hemp Processing

Fitzpatrick is a worldwide leader in providing superior hammer milling equipment for particle size reduction for cannabis and hemp processing.

YOUR CHALLENGES

Milling Cannabis & Hemp

Hemp plants are tough to mill and need a robust processing system that will last.

To ensure maximum yield, it is important to achieve consistent particle sizes from the hemp material. If the particle size is too large, not all of the yield is captured.

HOW WE CAN HELP

Equipment For Cannabis & Hemp Processing

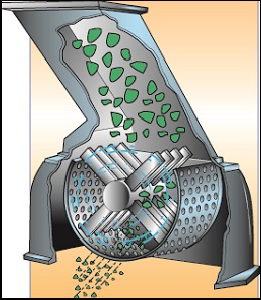

FitzMills are robust hammer mills that can successfully process hemp materials that are notoriously tough and fibrous. Our equipment is fully scalable to meet your production demands, whether you’re looking to process material for extraction or reduce the size of the product.

The FitzMill™ approach to reliability and precision will ensure that you consistently achieve the required target particle size, thereby guaranteeing that you maximize your hemp yields.

With an international network of test labs, field-based service & application technicians, as well as decades of testing and production experience with many formulations, Fitzpatrick is well-versed in what is necessary in order to provide effective pre /post-Sales support to our customers around the world.

OUR EXPERIENCE

In-Depth Application Knowledge

With many decades of experience across a variety of industries, we bring this knowledge to the cannabis & hemp processing sector.

Our robust equipment is widely recognized for being reliable and successful as it relates to the creation of the right particle size for many difficult-to-process materials.

OUR APPROACH

Hammer Milling Technology For Cannabis & Hemp Manufacturers

Fitzpatrick offers industry-leading equipment along with extensive experience achieved as a result of many decades of experience.

The Fitzpatrick Team adopts a consultancy approach to ensure you have the right mill to fulfill your cannabis and hemp processing requirements.

LET US HELP YOU NAVIGATE YOUR NEXT STEPS

Request a Callback With a Member of Our Team

For assistance with your cannabis and hemp milling challenges, please complete the form below to request a callback from one of our application engineers.

EQUIPMENT

Hammer Milling Machines For Cannabis & Hemp Processing

Fitzpatrick works with their customers to ensure we provide them with the ideal solution to benefit their manufacturing process.

When investing in our equipment, you obtain access to our Team of experts who will help you to get the best from your System for years to come.

Fitzpatrick is part of IDEX MPT, Inc., a group of companies who deliver a wide range of cannabis processing technologies for market-leading products.

They include:

- Microfluidics Cannabis Oil Processing Equipment

- Quadro Liquids High-Shear Mixing Equipment For Liquids & Powder Dispersion

- Quadro Engineering Milling Equipment For The Cannabis Industry

Please Note - Fitzpatrick information and literature is intended only for the use of its equipment in jurisdictions where such activities are legal.