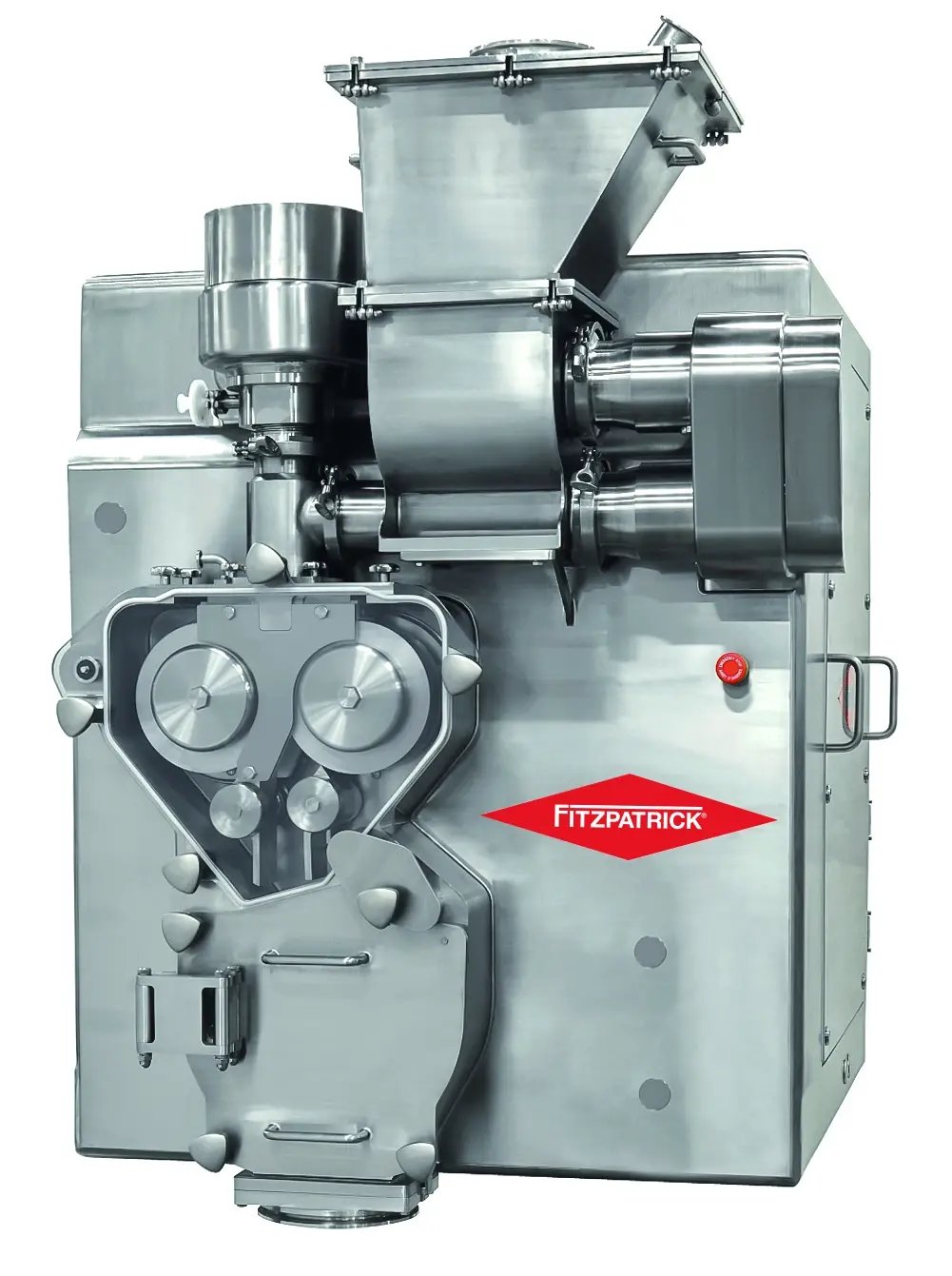

High Containment Roller Compaction

Precise, clean, fast dry granulation equipment

High containment levels designed for high specification needs and demanding projects, the CCS range delivers effective dry granulation and compaction for pharmaceutical, Chemical and Food product manufacturing.

BENEFITS

High Containment Roller Compaction

Decades of delivering world-class dry-granulation.

The CCS series offers a truly scalable growth path from models ideal for R&D development, right up to the high capacity large production-scale models.

High-quality results are thanks to our unique dual-screw feed system design which ensures the ideal conditions are created right from the outset at the critical nip area of the rolls.

Our range of CCS Roll Compactors are inherently well sealed with vacuum-tight security. But where even higher containment levels are demanded, our patented Product Containment System (PCS) with nitrogen inerting and security interlock is available.

The robust design gives you a machine with a long lifespan for a solid return on your investment. With minimal components to maintain or clean, production up-time is maximized.

All CCS models share the same design, making it easier for cleaning and maintenance as knowledge is completely transferable. Standardized HMI screens enable your Operators to run any machine. Additionally, results on lab and pilot models are directly scalable to larger units.

CCS220

R&D TO PRODUCTION

Ideal for R&D proof of concept research.

Benefits

- Directly scalable to production equipment as the roll diameters are identical.

- Compact, mobile unit which is easily movable.

- Uses the same body as the CCS320 so retrospectively convertible to a CCS320 by changing rolls.

- Isolator-ready for rigid/flexible wall.

- Laminar flow booth arrangement.

- Wash-in-place capabilities.

- Customization is available to suit specific needs.

Related Resources

ENQUIRE

2 X 20 cm

ROLL DIMENSIONS

26 kN/cm

ROLL FORCE

1-6 mm

ROLL GAP

Up To 25 kg/hr*

CAPACITY

CCS320

SMALL VOLUME PILOT-SCALE

Ideal for small volume and pilot-scale research.

Benefits

- Directly scalable to production equipment as the roll diameters are all identical.

- A compact, mobile unit which is easily movable.

- Isolator-ready for rigid/flexible wall.

- Laminar flow booth arrangement.

- Wash-in-place capabilities.

Related Resources

ENQUIRE

3 X 20 cm

ROLL DIMENSIONS

17 kN/cm

ROLL FORCE

1-6 mm

ROLL GAP

Up To 75 kg/hr*

CAPACITY

CCS520

MID-SIZED CAPACITY

Production scale equipment for mid-sized capacities.

Benefits

- Standard design is suitable for either free-standing or in-wall installation.

- In-wall installation minimizes GMP room size and removes the need for PPE when accessing the technical area.

- Uses the same body as the CCS720 with roll sizes changed.

- Freestanding or In-wall installation.

- PCS – Product Containment System

increasing containment rates and security. - Wash-in-place capabilities.

Related Resources

ENQUIRE

5 X 20 cm

ROLL DIMENSIONS

26 kN/cm

ROLL FORCE

1-6 mm

ROLL GAP

Up To 150 kg/hr*

CAPACITY

CCS720

PRODUCTION SCALE CAPACITY

Production scale equipment for larger capacities.

Benefits

- Available as through-wall installation to facilitate easy maintenance or reduce cleanroom needs.

- Uses the same body as the CCS520 with roll sizes changed.

- Floor or Through-wall installation design.

- PCS – Product Containment System

increasing containment rates and security. - Wash-in-place capabilities.

Related Resources

ENQUIRE

7.5 X 20 cm

ROLL DIMENSIONS

17 kN/cm

ROLL FORCE

1-6 mm

ROLL GAP

Up To 250 kg/hr*

CAPACITY

CCS1025

HIGH VOLUME CAPACITY

The largest volume capacity of the range.

Benefits

- With the in-wall installation, the Technical Area is entered from the back for ease of use without the need for PPE.

- Floor or Through-wall installation design.

- PCS – Product Containment System

increasing containment rates and security. - Wash-in-place capabilities.

Related Resources

ENQUIRE

10 X 25 cm

ROLL DIMENSIONS

20 kN/cm

ROLL FORCE

1-6 mm

ROLL GAP

Up To 400 kg/hr*

CAPACITY

Accreditations

As well as meeting the requirements of cGMP, we want to ensure that the milling machines we develop are well-designed and safe for the operator. To do this we always follow a variety of specific industry directives.

We offer a complete selection of ATEX and UKEX certified mills that meet the European Union directives and UK Safety Regulations for products used in potentially explosive atmospheres.

Our equipment is designed to handle the toughest milling applications, which is why professionals around the world choose Fitzpatrick. With models specifically designed to meet Ex Zone 0,20 (1GD) or 1/21 (2GD) requirements, we provide the most comprehensively safe mills in the industry.

ATEX compliant milling equipment

All equipment destined for Europe is CE-marked and UKCA-marked for Great Britain. It comes with an EU or UK Declaration of Conformity or Declaration of Incorporation. European equipment is certified to comply with the Machinery Directive 2006/42/EC, the Low Voltage Directive 2014/35/EU the Electromagnetic Compatibility Directive 2014/30/EU. British equipment is certified to comply with the 2008 Supply of Machinery (Safety) Regulations, 2016 Electromagnetic Compatibility Regulation, and the 2016 Equipment and Protective Systems Intended for Use in Potentially Explosive Atmospheres regulations.

Our equipment is designed to meet a variety of international safety standards, ensuring that whichever country you are in, we can certify compliance.

Our Range of Customer-Driven, Innovative Solutions

We offer solutions that provide reliable and repeatable results in the following areas:

Related Resources

- What is Dry Granulation?

- Learn how to optimize your Dry Granulation process

- Our Roller Compaction Technology

- Scalable Benchtop Dry Granulation

- Roller Compaction For Pharmaceutical Manufacturing

- Roller Compaction Technology For Food Manufacturing

- Roller Compaction In Nutraceutical Manufacturing

- Roller Compaction In Chemical Manufacturing

- Pharmaceutical Dry Granulation with Roll Compactors

- What Are The Benefits Of The Dry Granulation Method In Pharmaceuticals?

.webp)

.webp)