Manufacturers looking to purchase roll compactors are looking for equipment that incorporates performance, reliability, and longevity. The availability of aftermarket support is also extremely important.

The Fitzpatrick Company has been designing, developing, manufacturing, and testing roll compaction equipment for more than seven decades. Each new generation of machinery incorporates that knowledge.

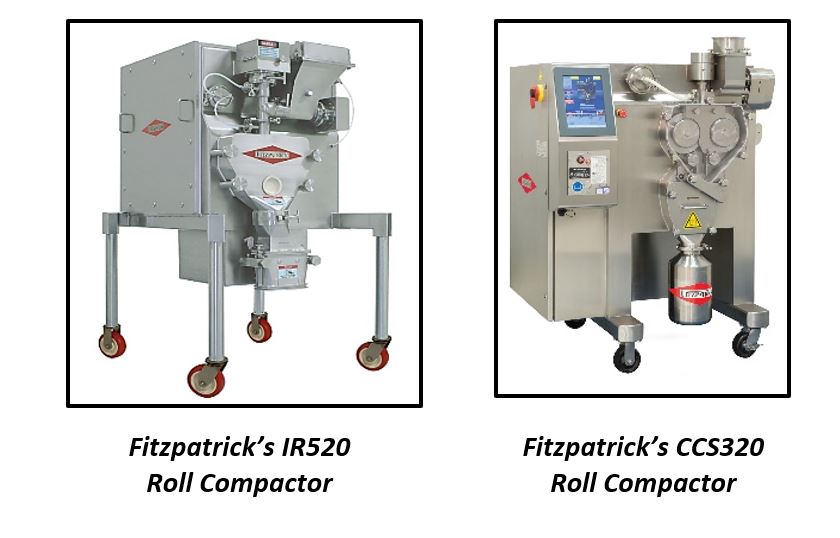

Fitzpatrick roller compactor equipment

We understand that targeted processes require specific roller compaction & milling equipment operating features and Fitzpatrick offers two distinct model ranges; the IR (Interchangeable Rolls) Series and the CCS (Contained Compaction Systems) Series. But how do you decide which one is right for you?

Let’s evaluate the similarities of our roll compactors

The IR and CCS-Series of roll compactors are both produced in Waterloo, ON, Canada by the same Production Team. Both systems are manufactured utilizing the same high-quality materials and are designed to withstand a long life of robust use. At Fitzpatrick, there is no two-tiered support system. Regardless of which equipment is purchased, every customer can anticipate the same high level of aftermarket support.

Capacity throughput for equivalent-sized equipment is comparable. However, the feed and roll controls on the CCS-Series models are somewhat more sophisticated resulting in the potential for a slightly higher yield.

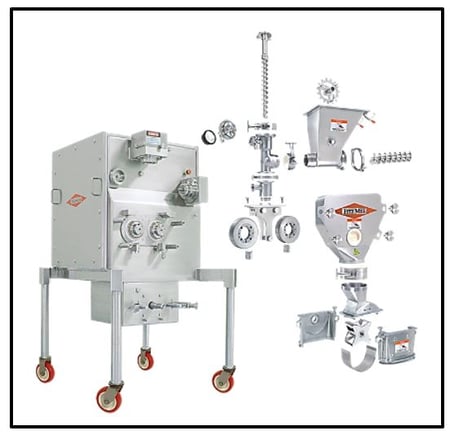

Fitzpatrick utilizes the same general design standards for both models, incorporating independent horizontal and vertical feed screws to optimize the presentation of the powder to the Nip Region. This System enables the best compression or tamping of the powder, and inherent deaeration of the feed powders so that the cantilevered rolls can produce a consistent compacted ribbon.

Both IR and CCS-Series models utilize the world-class FitzMill™ to mill and granulate the ribbon. Process flexibility is maximized by Fitzpatrick’s unique ability to select either a knife or bar rotor, in addition to having access to an extensive range of perforated screens, including round-hole, rasp and Conidur™ options.

Either model can be incorporated into an integrated system to connect with upstream and downstream processes.

Both Series are scalable. The IR-Series of roll compactors offers varying levels of production capacities ranging from pilot to full-scale production systems with results that are directly transferrable from one model to another. The CCS-Series provides a truly scalable equipment growth path for models designed for R&D development, up to and including high-capacity production-scale models.

And now the differences between our roll compactors

The IR-Series is characterized as a budget or lower cost roller compaction solution wherein containment requirements are less stringent. IR models are available at a cost equating to approximately 30% less than that of the cost for the equivalent CCS-Series model - from a size perspective.

The CCS-Series affords a higher performance solution for more demanding dry granulation applications. CCS models are designed for high containment. Should a specific application require an OEB4 level of containment, inertion and vacuum-grade sealing, Fitzpatrick recommends the CCS-Series. Models can also be fully contained if an OEB5 level of containment is deemed to be necessary.

IR-Series models are designed to facilitate complete disassembly. All the product contact parts can be removed from the machine with the exception being the flat back plate of the process area, which is a component of the equipment shell.

Many of the process contact parts of the CCS models can be removed from the machine but the housings of the roll and mill assemblies are monobloc-welded to the shell. This design guarantees high containment sealing, as previously mentioned. The housings are smooth-welded and radiused for easy in-situ cleaning. CCS models can also be equipped with WIP (Wash-In-Place) nozzles to flush the machine prior to it being opened.

The CCS-Series of roll compactors are more compact and can be “in-wall” mounted to create additional space within a clean room environment.

Our dry granulation equipment in summary…

There are certainly other less noteworthy differences that exist between the IR and CCS-Series of roll compactors; however, those that are likely to factor into a decision-making process have already been addressed.

Please contact us to discuss your specific application. We would be pleased to work with you to determine which machine options are preferable and would best facilitate your process.

Topics:

Roller Compaction